ball mill sizing and design yatra .

Ball Mill Design Calculation ... ball mill sizing selection – Grinding Mill China. Posted at:December 24,Ball Mill Sizing,Design Of Ball of ball ...

WhatsApp)

WhatsApp)

Ball Mill Design Calculation ... ball mill sizing selection – Grinding Mill China. Posted at:December 24,Ball Mill Sizing,Design Of Ball of ball ...

Notes on Ball Mill Design Power Draw. Power Draw is steady running power requirement ... ignoring drivetrain losses and startup loads. Power Draw is reduced for ...

There are three principal methodologies for sizing SAG mills that are ... feed size) and because this is a "singlestage ball mill" calculation, the... Mill ...

Calculation of energy required for grinding in a ball mill. ... Calculation of Energy Required for Grinding in a ... of energy required for grinding in a ball ...

The mill sizing page: Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single ...

modeling the specific grinding energy and ... modelling the specific grinding energy and ballmill scaleup ... mill power draw calculation ...

How Can I calculate new ball size and weight desing for ball mill. Dear All Expert, Our ball mill has got two compartments. But soon we will building roller press ...

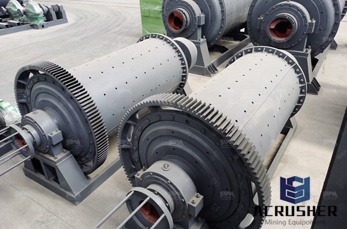

grinding and sizing ball mill ... ball mill sizing calculation Grinding Mill China. Ball mills are used primary for single stage fine grinding, regrinding, ...

Here is your Ball Mill Design/Sizing Procedure. Calculation of top size ... The ball sizing formulas from the literature on ball diameter selection do not take ...

Ball Mill Design/Power Calculation Mineral. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; ...

· I need to design a l end discharge ball (tube) mill for grinding kaolin as my engineering design project. where can I find necessory steps to follow the ...

· My grinding mill has length and diameter of m. the maximum size of the balls selected is 77 mm, as there are two or three kinds of ball sizes used ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

How to Size a Ball Mill Design Calculator Formula. ... Ball milling – a ball mill with a diameter of meters, inside new liners, grinding wet in open circuit.

Ball Mill Design/Power Calculation Mineral. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material ...

The model for optimal charge in the ball mill J. Min. Met. 43 A (2007) 21 For the requirements of the first part of investigations samples of quartz sand have been ...

mine ball mill sizing explanation; mine ball mill sizing explanation. The process design of gold leaching and carbonin . deep underground mine. In this case, ball ...

selection of rod mill | regrind ball mill sizing calculations – SBM Machine. CachedSelection rod mills, ball mills and regrind mills. in Book entitled: Mineral ...

SUMITOMO KAGAKU 2007II 2 Design Method of Ball Mill by Discrete Element Method of the balls are in a state where they are covered with the solid materials.

Ball Mill Design,Ball Mill Sizing,Design Of Ball Mill. ... derivation to calculate critical speed of ball mill . design calculation of ball mill; ...

Ball Mill Motor Sizing and Design Calculation Parameters. Motor Sizing Determination leftpanel. 0. Mill Power, kW KiloWatts Balls : Fraction of the Total Mill Power ...

allis ball mill Crusher Price. Section 6 Ball Regrind Mill Reloion at a Minnesota mine 1961, Crushing and Grinding Calculations, Allis Chalmers Tech. Pub. Allis ...

Ball mill sizing: Calculator for ball mill(s) in a single stage circuit. Rod ball mill sizing: Calculator for rod mill(s) as first stage of the circuit and ball ...

ball mill sizing sale_McMasterCarrMcMasterCarr supplies products used to maintain manufacturing plants and large commercial facilities Pocket Curtains ...

WhatsApp)

WhatsApp)